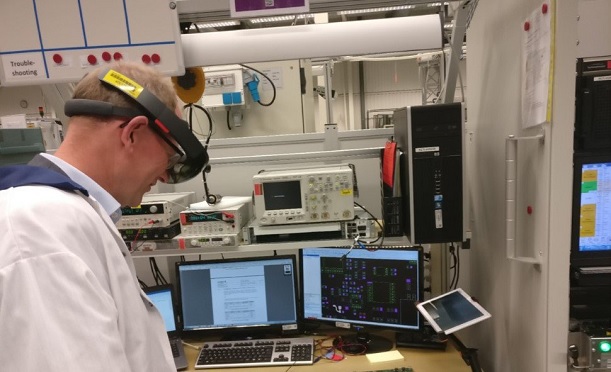

Ericsson researchers have started exploring how augmented reality can be used to troubleshoot problems with factory equipment.

Workers at one of the vendor’s factories in Tallinn, Estonia, have been using the technology to help them learn and share information about the building of products, such as circuit boards and components.

The Sweden-based company said it is roadtesting the technology to remove the “high workload” required to create, edit and update related documents, in addition to training staff.

Mihkel Tedremaa, Product Technology Manager, explained: “We found out that while working on a faulty unit, roughly half of a technician’s time goes to non-value add activities such as finding and linking schematics with layout files, fault info and troubleshooting instructions.”

The technology also makes it easier and quicker to send data between different factories. Tedremaa added: “If, for example, our engineers solve a very tricky issue this information could immediately reach our sites in China. The just-in-time fault-finding data, combined with better ergonomics and faster information sharing, can boost productivity by 50 percent.”

Two Ericsson facilities in Tallinn are using the technology but the vendor said it is hoping to roll it out further, including to its premises in Nanjing, China. It said further detail and troubleshooting advice for other products will also be added in future.

Tedremaa added: “Augmented reality troubleshooting is an incredibly simple solution for understanding functional parts of products and to share information between teams and sites.”

Augmented reality is just one of the technologies that Telecom Italia is researching in its Milan lab. Last month Vodafone announced it was exploring how mobile edge computing could be used to benefit AR.